Tube Inspection: Inspecting the Inner Wall of Tubes Using Customized Imaging and AI-Powered Software

Book a call

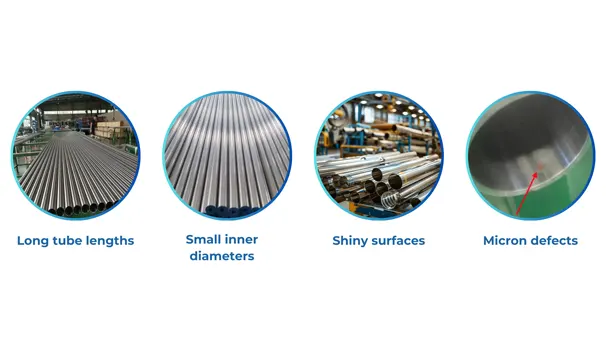

Inspecting the inner walls of tubes, particularly metal or plastic tubes, is a critical process in industries such as aerospace, automotive, and oil & gas, where precision and quality are essential. The inherent challenges of tube inspection—small inner diameters (ID), long lengths, and the need for high-resolution imaging—demand advanced, customized solutions. Combining cutting-edge imaging devices with AI-powered inspection software and custom electromechanical systems, manufacturers can achieve unparalleled accuracy and automation.

The inspection of a tube's inner wall presents unique challenges:

To ensure effective inspection, several critical factors must be considered:

The choice of imaging device depends on the tube’s ID, defect size, and length. Here are the most commonly used imaging technologies:

Customized CIS Camera Module:

Lighting is critical for capturing detailed images of the inner wall. Key considerations include:

Proper Illumination:

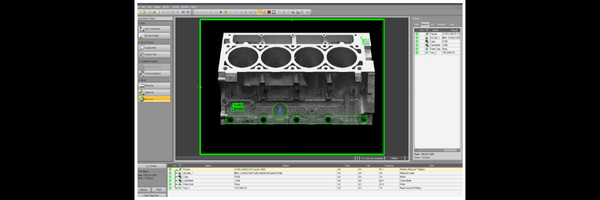

AI-powered defect detection software is the backbone of the inspection process. Its capabilities include:

Advanced AI Algorithms:

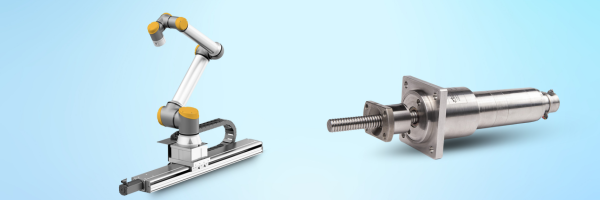

Automating tube inspection requires a customized electromechanical system tailored to the specific application. Key features include:

Uniform Movement Mechanism:

Customized imaging and AI-powered inspection systems are essential in various industries:

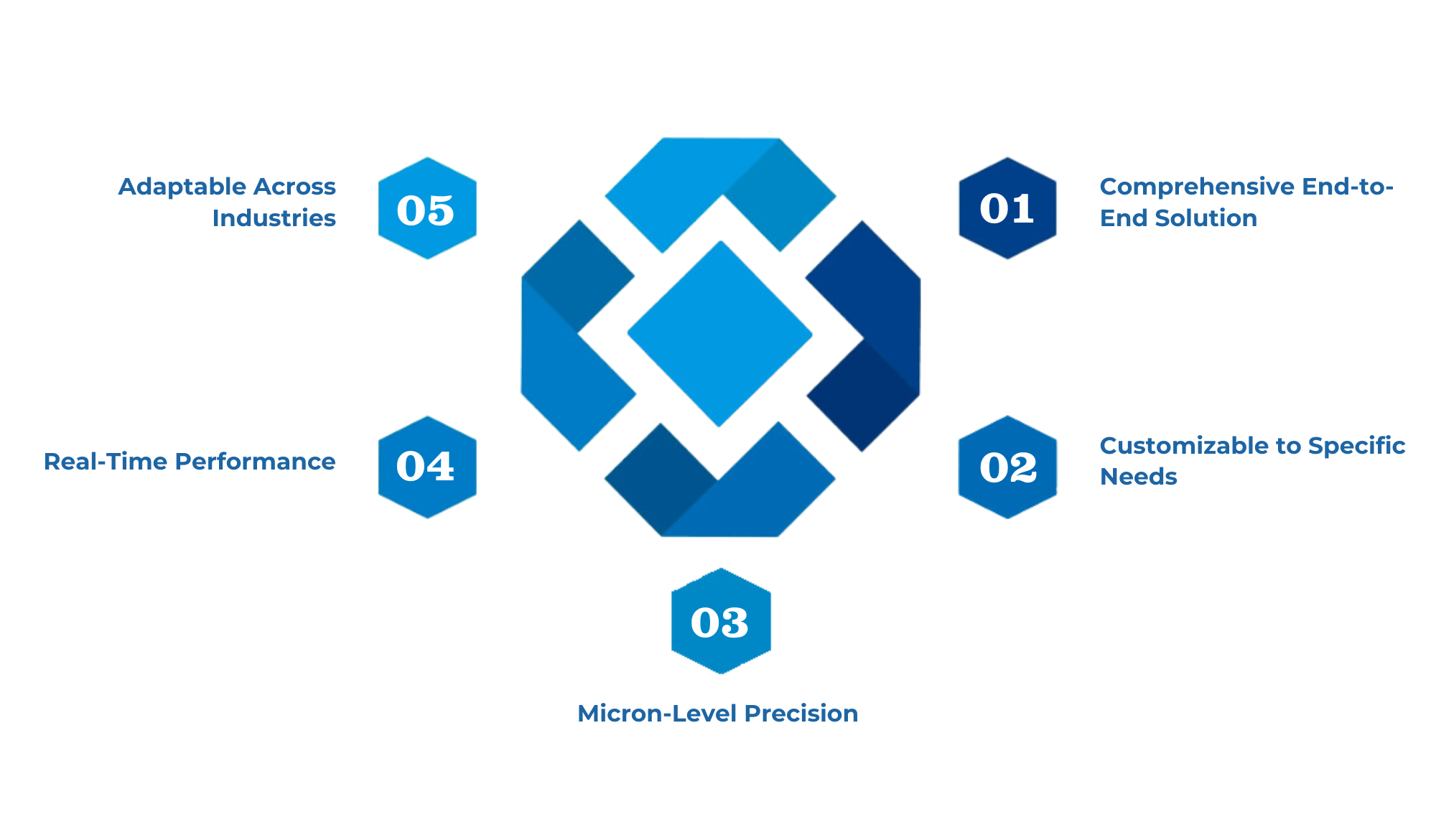

Intelgic’s Live Vision AI software and its complete suite of customized imaging devices and electromechanical systems provide an end-to-end solution to address these challenges, making it the ideal choice for automating tube inspection processes.

Intelgic's Live Vision AI is designed to work seamlessly with various imaging devices, making it an unmatched solution for inspecting the inner walls of tubes. Here's how it excels:

Proper lighting is crucial for capturing high-quality images of the inner wall surface. Intelgic designs lighting solutions tailored to fit inside tubes while ensuring optimal illumination:

Intelgic supplies a range of imaging solutions tailored for inner wall inspection, ensuring that the right technology is used based on the tube's size, material, and inspection requirements.

CIS Imaging Sensors for Long Tubes:To achieve a consistent and reliable inspection process, Intelgic collaborates with its partners to design and build custom electromechanical systems tailored for tube inspection:

Uniform Motion Mechanisms:

Inspecting the inner walls of metal tubes is a complex yet essential task in industries requiring high precision. By combining customized imaging solutions—such as CIS modules, machine vision cameras, and specialized miniature cameras—with AI-powered defect detection software, manufacturers can overcome the challenges of narrow IDs, long lengths, and micron-level defects. Coupled with customized electromechanical systems, these solutions enable efficient and automated inspection processes, ensuring product quality and reliability in critical applications.

With ongoing advancements in imaging technology and AI, tube inspection systems will continue to evolve, offering even greater accuracy, flexibility, and efficiency for manufacturers worldwide.

©2025 Intelgic Inc. All Rights Reserved.